| Annealing | Quenching |

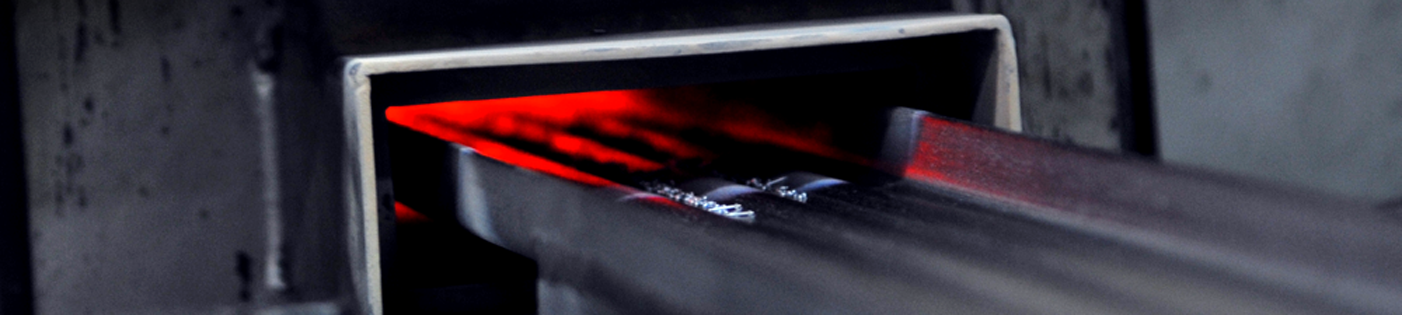

| Annealing is a process that involves heat treating a material to give it a required hardness level. It is usually applied to steel and copper alloy parts and can deliver a hardness range of 300Hv to 800Hv for steel, and 100Hv to 500Hv for copper alloy. | The quenching process is applied to heat treat materials to make them hard and brittle. The process, which heats parts up to 1,400 degrees Celsius, can be applied to all types of small steel parts, such as watch parts. |